Remember to decide on metropolis title rather than state. Remember to decide on locale of the plot. Pincode of the plot / land*

We'd like your tackle to produce a draft get. Please offer your deal with to create a draft purchase. Draft order continues to be produced efficiently. You are able to open or copy this link for the Bill checkout.

strong coatings applied to the skin of standard claddings intended to lower corrosion, maximize wear resistance, and decrease the production of hydrogen below high-temperature (incident) circumstances

Numerical and experimental review of armour method consisted of ceramic and ceramic- elastomer composites

Covington's eight" common glass laps are an economical option for grinding modest glass pieces. The #5070 lap features Covington's signature silicon carbide procedure consisting of 1 Every 100g and 400g silicon carbide sanding discs and a felt polishing disc Each individual affixed to particular person aluminum heads.

Polymeric membranes have previously been preferred because of their affordable and ease of scalability. Yet, this type of membrane suffers from small mechanical, chemical, and thermal security. Moreover, it can not withstand frequent and intense chemical cleaning, very important to retaining fantastic hygiene benchmarks in many industries.

Conformality in the deposition technique, nonetheless, requires a deposition thickness a minimum of equivalent to your sacrificial layer. As a result one particular are not able to go under a certain initial membrane layer thickness. The present method is expected to unravel these kinds of difficulties in CMUT fabrication. The present technique keeps the substrate wholly flat even immediately after sacrificial patterning, that's why aiding the consecutive method actions which include electrode deposition and patterning. The described technique does not maximize approach complexity other than an additional RIE stage. Using this technique CMUTs with five.6 MHz Centre frequency have been produced and tested.

The coating product containing the silicon carbide is dried and sintered. This method ensures a strong bond with the copyright product and provides the silicon filter membrane with its distinctive ruggedness and sturdiness.

For another thing, Despite the fact that silicon lets electrons whizz through its structure quickly, it really is significantly less accommodating to “holes�?�?electrons�?positively charged counterparts �?and harnessing both is important for a few kinds of chips.

Crossflow filtration is actually a filtration technique where the feed move is tangential on the surface in the tubular membrane filter in order to sweep rejected particles and solutes absent.

Think about what boron arsenides can realize, with ten moments higher thermal conductivity and far higher mobility than silicon. It can be a gamechanger.”

Unlike to polymeric membranes, silicon carbide ceramic membranes provide mechanical, thermal, and chemical strength �?all of which incorporate to an extended membrane life time than polymeric membranes can give. Moreover, ceramic membranes have a higher hydrophilicity level, which provides higher water fluxes and much less membrane fouling problems than their polymeric counterpart.

Recrystallized silicon carbide brick is really a will silicon carbide turn red hot on a cutting refractory content specifically bonded to silicon carbide with silicon carbide as Uncooked product which is characterised via the existence of no next period, made up of one hundred% alpha -SiC.

Improved fabrication of silicon carbide membranes for wastewater treatment method: From laboratory to industrial scale.

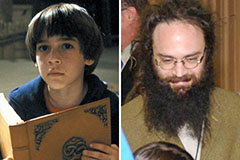

Barret Oliver Then & Now!

Barret Oliver Then & Now! Kirk Cameron Then & Now!

Kirk Cameron Then & Now! Mackenzie Rosman Then & Now!

Mackenzie Rosman Then & Now! Meadow Walker Then & Now!

Meadow Walker Then & Now! Kerri Strug Then & Now!

Kerri Strug Then & Now!